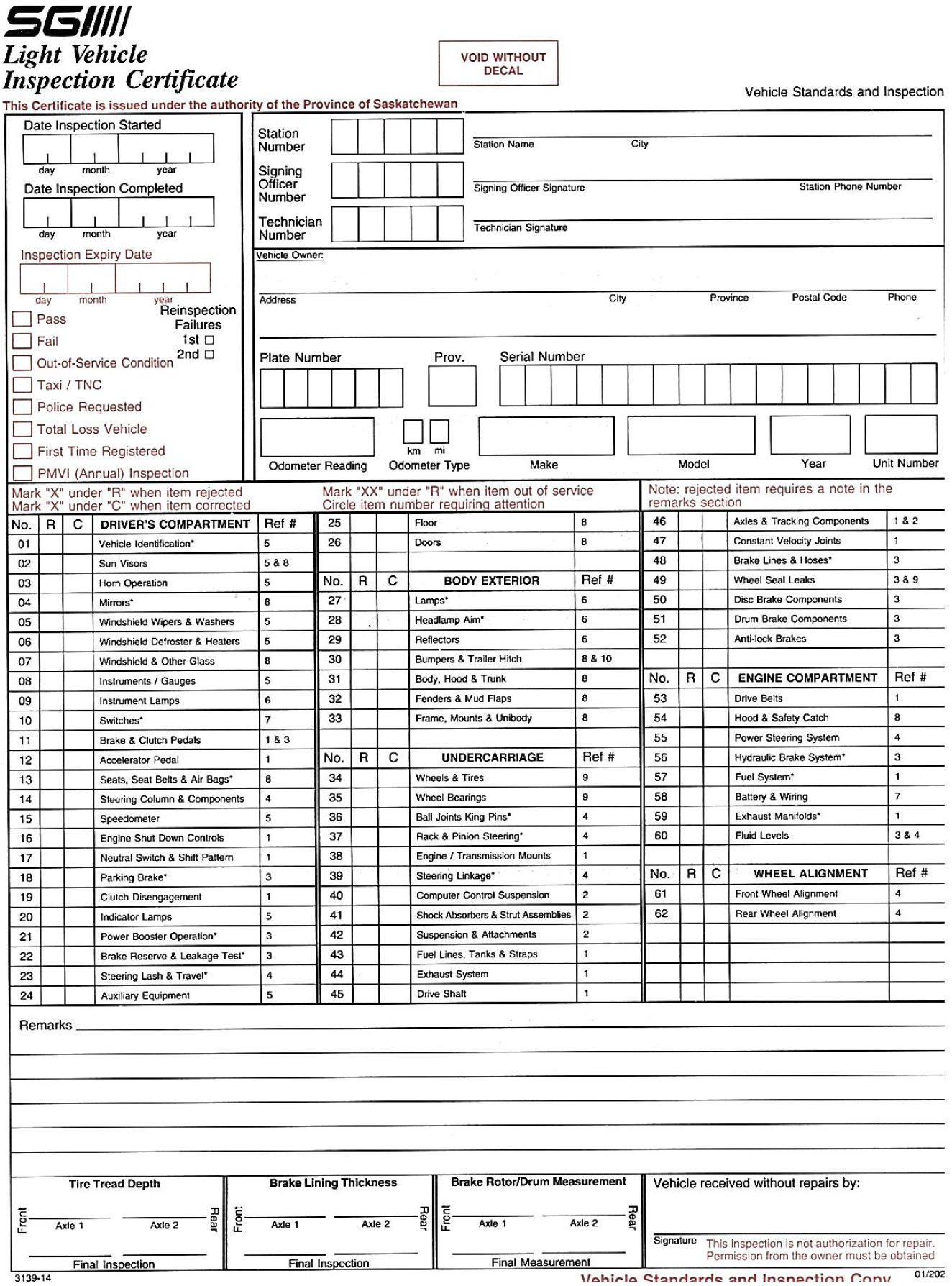

SGI SAFETY INSPECTION CHECKLIST

Review the inspection list ahead of time

Book Safety Inspection View the Form

Out of province Inspections in Saskatoon, Saskatchewan

So you bought a car from out of province. Now what? It's super simple! You bring the car down to Performance Plus, a Certified SGI Inspection Station, and our team of mechanics will perform an inspection using the required SGI Checklist and do a wheel alignment check for $129! If your vehicle meets SGI minimum requirements, you take a copy of the inspection to an SGI license issuer and buy your plates! Easy!

Although, if your vehicle doesn’t meet the minimum requirements, the Performance Plus team will give you a “no strings attached” quote for the repairs! You can repair the vehicle yourself and bring it back to us at no charge for the passing grade.

How much does an out of province inspection cost in Saskatoon, Saskatchewan?

- Out of province inspection in SK costs $129 + SGI decal.

Do I have to pay for a 2nd inspection if the vehicle fails?

- NO, Performance Plus will perform the reinspection for FREE if it is repaired within 30 days from the original inspection. The only exception is if we have to remove any parts or check the wheel alignment again.

Can Performance Plus repair any failed items?

- YES, we offer the best prices on auto parts of your choice and a competitive labor rate of $139/hr.

View the Official SGI Safety Inspection List

For an explanation of what we are required to report to SGI for each part of the vehicle inspection in Saskatoon, scroll down to below the inspection form.

Download the Official SGI Safety Inspection Form

See all 62 points of the SGI safety inspection with explanation here

SGI Safety Inspections Out of province Inspections in Saskatoon, Saskatchewan. So you bought a car?

Driver's Compartment

1. Vehicle Identification

What does SGI mean by 'vehicle identification'?

This is simply checking the vehicle VIN. A Vehicle Identification Number (VIN) is a unique code assigned to every vehicle when it's manufactured. Think of it like a car's fingerprint. The VIN is made up of 17 characters, which include both letters and numbers. It provides important information about the vehicle, such as the manufacturer, model, year of production, and where it was made. You can usually find the VIN on the dashboard near the windshield or on the driver's side door frame. It's used for various purposes, like tracking recalls, registrations, and insurance.

How is vehicle identification checked at an SGI inspection?

During an SGI (Saskatchewan Government Insurance) safety inspection, vehicle identification is verified by checking the Vehicle Identification Number (VIN). The inspector will cross-reference the VIN against the vehicle's registration documents and databases to confirm it matches the vehicle's make, model, and other details. This ensures that the vehicle is properly identified and aligned with the official records. The VIN can typically be found on the dashboard near the windshield, the driver's side door frame, or other designated locations depending on the vehicle's make and model. This process helps to prevent fraud and ensures that the vehicle meets provincial safety standards.

2. Sun Visors

The inspection criteria for sun visors in light vehicles are as follows:

- Location: The sun visor must be present on the driver's side.

- Attaching Parts: The sun visor must not be missing, broken, bent, or loose. 1

- Adjustment: The sun visor must be able to be maintained in a set position.

- Modified or Non-OEM Sun Visor: The sun visor must meet the OEM standard.

For vintage vehicles or modified vintage vehicles, an interior sun visor is not required if it was not installed by the original manufacturer.

3. Horn Operation

Horn Requirement's:

Horn is required to make a sound

4. Mirrors

Rear view Mirror:

- Every vehicle is required an external rear-view mirror on the left side.

- When a vehicle does not have an interior rear-view mirror that provides an obstructed view through the rear window, a external mirror is also required on the right.

- Location

- Vision

- Mount

- Glass Condition

- Surface area of external mirror

Rejected If:

- Rear view mirror is missing

- view to the rear is obstructed on a required mirror

- Broken, insecure, or loose

- Fails to hold mirror in position

- Cracked

- Vision is obscured due to condition of glass or surface

Out Of Service / Hazardous Condition:

- External rear view mirror is missing, obscured, insecure, or adjustment is seized.

5. Windshield Wiper & Washer

Operation:

- Windshield wipers must operate on all speeds.

- They must park correctly when turned off.

- They must be functional and not inoperative.

Blades:

- Wiper blades must not be torn, hardened, or missing.

- They must wipe approximately 75% of the windshield.

- The swept area must meet OEM wiper blade standards.

- Blades must contact the windshield properly.

Arms:

- Wiper arms must not be missing, broken, or bent.

- They must not be distorted and should meet OEM standards.

Washers:

- Windshield washers must be present and operable.

- They must direct sufficient washer fluid at the correct position on the windshield.

Out of Service / Hazardous Condition:

- The wiper on the driver's side must not be inoperative or missing any parts that render it ineffective.

For vintage vehicles:

- Vehicles from 1970 and older must have at least one functional windshield wiper that clears the driver's side of the windshield.

- Vehicles from 1971 and newer must have two windshield wipers that comply with the standards or inspection criteria set out in the manual.

6. Windshield Defroster & Heater

Windshield Defroster:

The windshield defroster and heater must be operational at all settings, provide adequate airflow, and deliver heated air. The heater core should not have a level 2 leak of coolant. If any of these conditions are not met, the vehicle will fail the inspection.

Heater:

For a vehicle to pass inspection, the windshield defroster and heater must be fully operational at all settings, provide adequate airflow, and deliver heated air. 1 Additionally, the heater core should not have any significant coolant leaks.

7. Windshield & Other Glass

Windshield:

- Must be laminated safety glass (ANSI Z26.1, type AS-1 or AS-10). 1

- No aftermarket tint film except within the top 75mm (2.95 inches). 2

- No cracks extending more than 50mm (2 inches) into the wiper-swept area or through both layers. 3

- Chips larger than 13mm (1/2 inch) in the wiper-swept area are not allowed.

- No more than 10% discoloration of the total glass area.

- Free from decals or devices in the wiper-swept area.

Side Windows:

- Must be ANSI safety glass (AS-1, AS-2, AS-10, or AS-11) for windows forward of the driver's seat back. 4

- Rearward windows not requisite for driving visibility must be marked as ANSI safety glass (AS-3, AS-4, or AS-5). 5

- Should not impair driver vision due to clouding, damage, or deterioration. 6

- No exposed sharp edges, broken parts, or missing sections. 7

- Any aftermarket tint film must comply with ANSI/SAE Z26.1 standards. 8

Rear Window:

- Must be marked as ANSI safety type AS-1, AS-2, AS-3, AS-10, or AS-11, or rigid plastic AS-4 or AS-5.

- No aftermarket tint film unless the vehicle has right and left outside mirrors providing a clear rear view

8. Instruments / Clusters

Speedometer:

- Must function properly.

- Must be clearly visible from the primary driving position.

- GPS or similar devices are not acceptable substitutes. 1

Brake Warning Indicator:

- Must function properly.

- Must be clearly visible from the primary driving position.

Anti-lock Brake System (ABS) Indicator:

- Must illuminate during the "test" position cycle.

- Must not remain illuminated with the parking brake released and the engine running.

Electronic Stability Control (ESC) Indicator (if equipped):

- Must function during the OEM test cycle.

- Must not remain illuminated with the engine running in a forward gear after moving at least 10 meters.

Tire Pressure Monitoring System (TPMS):

- Indicator lamp/system status lamp must illuminate during the bulb-check.

- Must not remain illuminated, indicating a fault or malfunction.

High Beam Indicator:

- Must illuminate when high beams are selected.

Turn Signal/Hazard Indicators:

- Must function properly.

- Proper indicator must illuminate for switch selection.

Supplementary Restraint System (SRS) Warning Lamp:

- Must illuminate during the OEM test cycle.

- Must not remain illuminated with the engine running.

Seat Belt Warning Indicator:

- Visual and audible warning systems must function as per OEM standard.

Electric Power Steering Indicator (if equipped):

- Must illuminate during the OEM test cycle.

- Must not remain illuminated or indicate a fault with the engine running.

Out of Service / Hazardous Condition:

- Any brake failure lamp that remains illuminated after the cycle.

- SRS warning lamp indicating a system malfunction.

9. Instrument Lamps

Shift Pattern - Automatic Transmission:

- Must be illuminated and clearly visible.

Speedometer Lamp:

- Must function properly and be clearly visible from the primary driving position.

Instrument Lamps or Backlighting:

- All required instruments or gauges must be properly illuminated or backlit

10. Switches

Headlamp Switch:

- Must be present, functional, and compatible with OEM specifications.

Dimmer Switch:

- Must be present, functional, and mounted as per OEM specifications.

Heater and Defroster Switch:

- Must operate on all speeds, be functional, and not broken or missing.

Turn Signal Switch:

- Must be present, functional, and hold the selected position.

- Must cancel automatically when the steering returns to the center (for OEM equipped vehicles).

Hazard Warning Switch:

- Must be present, functional, and not broken or missing.

Windshield Wiper and Washer Switch:

- Must operate on all speeds, be functional, and not broken or missing.

Ignition/Engine Start Switch:

- Must require a key (or key fob) to operate.

- Must be present, functional, and not broken or damaged.

- These switches must operate as per OEM design and be in good working condition.

11. Brake & Clutch Pedals

Brake Pedal/Actuator:

Pedal:

- Must not be broken, cracked, loose, missing, or abnormally worn. 1

- Must not be welded or repaired in a way that does not meet OEM standards. 2

Mount:

- Must not be cracked, deteriorated, insecure, or weakened by corrosion. 3

Anti-slip Feature:

- Must be effective, not loose or missing. 4

Clutch and Clutch Pedal:

Adjustment/Disengagement:

- Must function as per OEM standards. 5

- Must allow disengagement of the transmission from the engine.

Pedal and Linkage: 6

- Must not be broken, cracked, loose, missing, or abnormally worn. 1

- Must not be deteriorated or weakened by corrosion.

- Must not be welded or repaired in a way that does not meet OEM standards. 2

- Anti-slip feature must be effective, not loose or missing.

- Pedal extensions must be specifically designed and manufactured for the application.

Clutch Pedal Hydraulic System: 7

- Fluid reservoir must be above the minimum level indicated by the manufacturer.

- Must not have a level 2 leak of fluid at any point.

Out of Service / Hazardous Condition:

Brake Pedal:

- Pedal must not be missing.

Clutch Pedal:

- Must disengage the transmission.

12. Accelerator Pedal

Pedal/Actuator:

- Must not be missing or binding.

- Engine must return to the idle position when the pedal is released.

- Adjustable pedal must be operable.

- Throttle position sensor must operate correctly.

- Anti-slip material must not be missing, loose, or excessively worn.

13. Seats, Seat Belts, & Air Bags

Condition:

- Must be securely mounted and not loose.

- Seat frame must not be broken.

- Seat covering or energy-absorbing material must not expose or allow contact with metal components or springs.

- Seat assembly must meet OEM standards.

- Driver's seat must be adjustable forward and backward and lock securely in position.

- Seat back locks must be present, secure, and operable, holding the seat back in the locked position.

- Seats that adjust passenger positioning must lock into position.

Head Restraint (Head Rest):

- Must not be missing or damaged.

- Must function as per OEM or industry standards.

Seat Bolts:

Anchorage:

- Driver's seat must be securely anchored with no missing or loose anchor bolts/nuts.

- Passenger seat must be securely anchored unless otherwise installed by the original manufacturer.

Airbags (Supplemental Restraint System - SRS):

Condition:

- Airbag must not be disconnected, inoperative, missing, or not re-installed according to OEM service instructions.

- Airbag indicator (SRS) lamp must not indicate a malfunction and must operate according to OEM service instructions.

- Airbag must not be permanently deactivated without a provision to turn off and on by a key lock, and must have an illuminated message to indicate when the airbag is switched off.

Pre-tensioner and Load Limiter:

- Pre-tensioner must not be activated without repair or replacement to meet OEM or industry standards.

- Load limiter must not be activated without repair or replacement to meet OEM or industry standards.

Out of Service / Hazardous Condition:

Seats:

- Driver's seat must not be loose, insecure, or fail to lock into position.

Airbags:

- A required airbag must not be inoperative or missing

14. Steering Column & Components

Steering Column:

- Must be securely mounted.

- Mounting bolts must not be missing or loose.

- Tilt or adjustable column must comply with OEM free play and mounting standards.

- Coupler to the box must be properly aligned and not deteriorated or oil-contaminated.

- Clamp, bolt, nut, or locking roll pin must not be loose or missing.

Steering Shaft Universal Joint:

- Must not be loose, welded, seized, or binding.

- Clamping bolt must not be loose.

- Spline must not be loose or stripped.

- Rotational free play between splines must not exceed 1 mm (0.039 in.).

- Horizontal play must not exceed 6 mm (0.236 in.).

Pitman Arm:

- Must not be loose, welded, or have stripped threads.

- Attaching nuts must not be loose.

Steering Gear (Box or Rack and Pinion Unit):

- Housing or bracket must not be cracked or insecurely mounted.

- Bolts must not be loose or missing.

- Bellows (clamp and boot) must not be split, torn, or missing.

- Inner socket assembly must not be worn beyond OEM standards.

Mounting Brackets:

- Must not be cracked, damaged, or have missing bolts or clamps.

- Insulators must not be missing or loose.

Cotter Pins:

- Must not be missing or of inferior substitute.

Idler Arm:

- Must not be loose, welded, or have stripped threads.

Steering Shaft Yoke:

- Must not be loose, welded, or have stripped threads.

Slip Joint:

- Rotational free play between splines must not exceed 1 mm (0.039 in.).

- Horizontal play must not exceed 6 mm (0.236 in.).

Adjusting Sleeve:

- Must not be loose, bent, or welded.

- Pinch bolt must not be oriented in a position to contact other components and cause steering to bind or become jammed.

Out of Service / Hazardous Condition:

Steering Column:

- Any bolts are loose or missing.

- Any positioning parts allow movement from its normal position.

- Any universal joints are field welded.

- Steering wheel is not secure.

- Adjuster sleeve is loose.

Steering Box or Rack and Pinion Unit:

- Any mounting bolts are loose or missing.

- Any frame or mounting bracket is loose or cracked.

Pitman Arm:

- Loose on steering gear output shaft spline or field welded.

Ball and Sockets:

- Any linkage shows looseness in alignment with the shank or neck of the ball in excess of 3 mm (0.118 in.) 18 or adjusting sleeve is loose.

- Any socket is injected.

15. Speedometer

Operation:

- The speedometer must function properly.

- It must be clearly visible from the primary driving position.

Inspection Criteria:

- The speedometer must not be inoperative.

- It must not be obscured or difficult to read from the driver's seat.

Additional Notes:

- A GPS or similar device that uses satellite or RF signals to determine speed is not acceptable as a replacement for a speedometer.

Out of Service / Hazardous Condition:

- The speedometer must not be missing or inoperative.

16. Engine Shut Down Control's

Manual Shutdown (Cable): 1

- Must be operable and able to shut down the engine manually.

Ignition Switch:

- Must be operable and able to shut down the engine when turned off.

- Must not be damaged, missing, or inoperable.

Engine Shutdown Control Feature:

- Must be operable and able to shut down the engine when activated.

- Must not be damaged, missing, or inoperable.

Inspection Criteria:

Manual Shutdown (Cable): 1

- Must not be inoperable or unable to shut down the engine manually.

Ignition Switch:

- Must not be damaged, missing, or inoperable.

- Must shut down the engine when turned off.

Engine Shutdown Control Feature:

- Must not be damaged, missing, or inoperable.

- Must shut down the engine when activated.

Out of Service / Hazardous Condition:

- The engine shutdown control must be operable and able to shut down the engine as intended. 1 If any of the controls are inoperable, damaged, or missing, it is considered a hazardous condition

17. Neutral Switch & Shift Pattern

Operation:

- Vehicles with automatic transmissions manufactured on or after November 25, 1970, must be equipped with a neutral safety switch.

- Vehicles with a GVWR at or below 4,536 kg manufactured on or after June 18, 2003, must be equipped with a clutch safety switch.

Inspection Criteria:

- The neutral safety switch must prevent the engine from starting unless the transmission is in the neutral or park position.

- The clutch safety switch must prevent the engine from starting unless the clutch pedal is depressed.

Out of Service / Hazardous Condition:

- The vehicle must not start in any gear other than neutral or park (for automatic transmissions) or without the clutch pedal being depressed (for manual transmissions).

Shift Pattern:

Gear Position Indicator:

- Must be located in view of the seated driver.

- Must be operable and aligned with the gear selection.

Inspection Criteria:

- The gear position indicator must not be missing or illegible.

- The indicator must be aligned with the gear selection and operable with automatic transmissions.

Out of Service / Hazardous Condition:

- The gear position indicator must not be inoperable or misaligned, as this could lead to unsafe operation of the vehicle.

Summary:

- Neutral Switch: Must prevent the engine from starting unless in neutral/park or with the clutch pedal depressed.

- Shift Pattern: Gear position indicator must be visible, operable, and aligned with the gear selection.

18. Parking Brake

Operation:

- The parking brake must hold the vehicle stationary when applied.

- For manual transmissions, the parking brake should hold the vehicle in place when the transmission is in the second or third lowest gear, and the clutch is slowly engaged without applying the throttle.

- For automatic transmissions, the parking brake should hold the vehicle in place when the transmission is in a forward gear, and the engine speed is raised to no more than 800 rpm.

Indicator Lamp:

- The parking brake indicator lamp must activate when the parking brake is applied.

Control:

- The parking brake control must be operable and able to lock in place.

Cable and/or Linkage:

- The parking brake cable and linkage must be intact, properly secured, and not frayed or seized.

Adjustment:

- The parking brake system must be properly adjusted to ensure effective operation.

Friction Material:

- The friction material of the parking brake must be in good condition and not worn below the manufacturer's specifications.

Inspection Criteria:

Operation:

- The parking brake must hold the vehicle stationary as required.

Indicator Lamp:

- The parking brake indicator lamp must function correctly.

Control:

- The parking brake control must not bind, be broken, or missing.

Cable and/or Linkage:

- The cable and linkage must not be broken, frayed, improperly secured, missing, or seized.

Adjustment:

- The parking brake system must be properly adjusted.

Friction Material:

- The friction material must not be worn below the manufacturer's specifications.

Out of Service / Hazardous Condition:

- The vehicle must not roll forward or backward with little or no resistance when the parking brake is applied.

Summary:

- Parking Brake Operation: Must hold the vehicle stationary.

- Indicator Lamp: Must activate when the parking brake is applied.

- Control: Must be operable and lock in place.

- Cable and Linkage: Must be intact, properly secured, and not frayed or seized.

- Adjustment: Must be properly adjusted.

- Friction Material: Must be in good condition and not worn below specifications.

19. Clutch Disengagement

Adjustment/Disengagement:

- The clutch must allow the disengagement of the transmission from the engine.

- The clutch operation and adjustment must be according to the manufacturer’s service instructions.

Pedal and Linkage:

- The clutch pedal and linkage must be intact, properly secured, and not excessively worn or deteriorated.

Clutch Pedal Hydraulic System:

- The hydraulic system must be free of leaks and the fluid level must be within the manufacturer’s specified range.

Inspection Criteria:

Adjustment/Disengagement:

- The clutch must function as per OEM standards.

- The clutch must allow the disengagement of the transmission from the engine.

Pedal and Linkage:

- The pedal and linkage must not be broken, cracked, loose, missing, abnormally worn, deteriorated, or weakened by corrosion.

- The pedal must not be welded or repaired in a way that does not meet OEM standards.

- The anti-slip feature must be effective, not loose or missing.

- Pedal extensions must be specifically designed and manufactured for the application.

Clutch Pedal Hydraulic System:

- The fluid reservoir must not be below the minimum level indicated by the manufacturer.

- There must be no level 2 leaks of fluid at any point.

Out of Service / Hazardous Condition:

- The clutch must disengage the transmission. If it does not, it is considered an out-of-service condition.

Summary:

- Adjustment/Disengagement: The clutch must allow the disengagement of the transmission from the engine and function as per OEM standards.

- Pedal and Linkage: Must be intact, properly secured, and not excessively worn or deteriorated.

- Clutch Pedal Hydraulic System: Must be free of leaks and the fluid level must be within the manufacturer’s specified range.

20. Indicator Lamps

Operation:

- Confirm the location and labeling of brake indicator lamps according to manufacturer service instructions.

- Check the operation of brake indicator lamps according to manufacturer service instructions.

- When no manufacturer service instructions are available, begin with the engine stopped, then turn the ignition on. Lamps must turn on when the ignition is first turned on. Lamps may go out after 2-3 seconds or may stay on until the engine is started.

Types of Indicator Lamps:

Brake Warning Indicator:

- Must function correctly and be clearly visible from the primary driving position.

Anti-lock Brake System (ABS) Indicator:

- Must illuminate during the bulb-check cycle when the ignition is turned on and should not remain illuminated with the parking brake released and the engine running.

Electronic Stability Control (ESC) Indicator (if equipped):

- Must function during the OEM test cycle and should not remain illuminated with the vehicle engine running in a forward gear after the vehicle is moved over a distance of at least 10 meters.

Tire Pressure Monitoring System (TPMS) Indicator:

- The system is not required to function, but the warning lamp may illuminate due to low tire pressure, system malfunction, after-market rims, or tires of a different size than recommended by the manufacturer.

High Beam Indicator:

- Must illuminate when the high beam is selected.

Turn Signal/Hazard Indicators:

- Must function correctly, and the proper indicator should illuminate for the switch selection.

Supplementary Restraint System (SRS) Warning Lamp:

- Must illuminate during the OEM test cycle and should not remain illuminated with the engine running.

Seat Belt Warning Indicator:

- Visual and audible warning systems must function as per OEM standards.

Electric Power Steering Indicator (if equipped):

- Must illuminate during the OEM test cycle and should not remain illuminated or indicate a fault with the engine running.

Inspection Criteria:

Brake Warning Indicator:

- Must function correctly and be clearly visible from the primary driving position.

ABS Indicator:

- Must illuminate during the bulb-check cycle and should not remain illuminated with the parking brake released and the engine running.

ESC Indicator:

- Must function during the OEM test cycle and should not remain illuminated with the vehicle engine running in a forward gear after the vehicle is moved over a distance of at least 10 meters.

TPMS Indicator:

- The indicator lamp/system status lamp must illuminate during the bulb-check or lamp remains illuminated.

High Beam Indicator:

- Must illuminate when the high beam is selected.

Turn Signal/Hazard Indicators:

- Must function correctly, and the proper indicator should illuminate for the switch selection.

SRS Warning Lamp:

- Must illuminate during the OEM test cycle and should not remain illuminated with the engine running.

Seat Belt Warning Indicator:

- Visual and audible warning systems must function as per OEM standards.

Electric Power Steering Indicator:

- Must illuminate during the OEM test cycle and should not remain illuminated or indicate a fault with the engine running.

Out of Service / Hazardous Condition:

Brake Failure Lamp:

- Must not remain illuminated after the cycle.

SRS Warning Lamp:

- Must not indicate a system malfunction.

Summary:

- Operation: Indicator lamps must function correctly and be clearly visible.

- Types of Indicator Lamps: Includes brake warning, ABS, ESC, TPMS, high beam, turn signal/hazard, SRS, seat belt warning, and electric power steering indicators.

- Inspection Criteria: Must function correctly and not remain illuminated when they should not be.

- Out of Service / Hazardous Condition: Brake failure lamp and SRS warning lamp must not indicate a malfunction.

21. Power Booster Operation

Operation:

- Confirm the location and labeling of brake indicator lamps according to manufacturer service instructions.

- Check the operation of brake indicator lamps according to manufacturer service instructions.

- When no manufacturer service instructions are available, begin with the engine stopped, then turn the ignition on. Lamps must turn on when the ignition is first turned on. Lamps may go out after 2-3 seconds or may stay on until the engine is started.

Types of Indicator Lamps:

Brake Warning Indicator:

- Must function correctly and be clearly visible from the primary driving position.

Anti-lock Brake System (ABS) Indicator:

- Must illuminate during the bulb-check cycle when the ignition is turned on and should not remain illuminated with the parking brake released and the engine running.

Electronic Stability Control (ESC) Indicator (if equipped):

- Must function during the OEM test cycle and should not remain illuminated with the vehicle engine running in a forward gear after the vehicle is moved over a distance of at least 10 meters.

Tire Pressure Monitoring System (TPMS) Indicator:

- The system is not required to function, but the warning lamp may illuminate due to low tire pressure, system malfunction, after-market rims, or tires of a different size than recommended by the manufacturer.

High Beam Indicator:

- Must illuminate when the high beam is selected.

Turn Signal/Hazard Indicators:

- Must function correctly, and the proper indicator should illuminate for the switch selection.

Supplementary Restraint System (SRS) Warning Lamp:

- Must illuminate during the OEM test cycle and should not remain illuminated with the engine running.

Seat Belt Warning Indicator:

- Visual and audible warning systems must function as per OEM standards.

Electric Power Steering Indicator (if equipped):

- Must illuminate during the OEM test cycle and should not remain illuminated or indicate a fault with the engine running.

Inspection Criteria:

Brake Warning Indicator:

- Must function correctly and be clearly visible from the primary driving position.

ABS Indicator:

- Must illuminate during the bulb-check cycle and should not remain illuminated with the parking brake released and the engine running.

ESC Indicator:

- Must function during the OEM test cycle and should not remain illuminated with the vehicle engine running in a forward gear after the vehicle is moved over a distance of at least 10 meters.

TPMS Indicator:

- The indicator lamp/system status lamp must illuminate during the bulb-check or lamp remains illuminated.

High Beam Indicator:

- Must illuminate when the high beam is selected.

Turn Signal/Hazard Indicators:

- Must function correctly, and the proper indicator should illuminate for the switch selection.

SRS Warning Lamp:

- Must illuminate during the OEM test cycle and should not remain illuminated with the engine running.

Seat Belt Warning Indicator:

- Visual and audible warning systems must function as per OEM standards.

Electric Power Steering Indicator:

- Must illuminate during the OEM test cycle and should not remain illuminated or indicate a fault with the engine running.

Out of Service / Hazardous Condition:

Brake Failure Lamp:

- Must not remain illuminated after the cycle.

SRS Warning Lamp:

- Must not indicate a system malfunction.

Summary:

- Operation: Indicator lamps must function correctly and be clearly visible.

- Types of Indicator Lamps: Includes brake warning, ABS, ESC, TPMS, high beam, turn signal/hazard, SRS, seat belt warning, and electric power steering indicators.

- Inspection Criteria: Must function correctly and not remain illuminated when they should not be.

- Out of Service / Hazardous Condition: Brake failure lamp and SRS warning lamp must not indicate a malfunction.

22. Brake Reverse & Leakage Test

Vacuum Assist (Boost) System:

Brake Reserve Test:

Stage 1:

- Start the engine and build to full vacuum.

- Shut the engine off and make two full brake applications.

Stage 2:

- With the engine off, press the brake pedal several more times to eliminate remaining vacuum.

- Apply light force on the brake pedal and then start the engine.

- Downward movement of the brake pedal should be felt when the engine is started.

Leakage Test:

Line, Hose, and Clamp:

- Must be free of breaks, chafing, collapses, cracks, leaks, looseness, or missing parts.

- Must be securely mounted, of the correct type, and positioned at least 50 mm (2 in.) away from any exhaust system component unless protected by a heat shield.

Check Valve:

- Must be correctly installed, operational, free of leaks, and not missing.

Tank:

- Must be free of damage, structural deterioration from corrosion, secure, and not leaking or missing.

Vacuum Pump:

- Must operate within manufacturer specifications or achieve and maintain 4.5 kPa (18 in.) of vacuum.

Hydraulic Assist (Boost) System:

Brake Reserve Test:

Test Method 1:

- For a system with an electrically driven back-up pump, operate brakes with the engine running and engine stopped with the ignition off.

- Observe system operation and status of indicator lamps.

Test Method 2:

- For a system with a gas accumulator back-up, stop the engine and deplete the pressure reserve.

- Apply moderate force on the brake pedal and start the engine.

- The brake pedal should sink down and then push back up again.

Leakage Test:

Engine-Driven Pump, Reservoir, and Belt:

- Check with the engine stopped and with the engine running. Inspect the drive belt according to Section 1 (Power Train, Item 5 - Belt).

Line and Hose:

- Check with the engine stopped and with the engine running.

Operation:

- Confirm proper operation of the hydraulic assist (boost) system according to manufacturer service instructions. When no manufacturer service instructions are available, check as described below:

- Test Method 1: For a system with an electrically driven back-up pump, operate brakes with the engine running and engine stopped with the ignition off. Observe system operation and status of indicator lamps.

- Test Method 2: For a system with a gas accumulator back-up, stop the engine and deplete the pressure reserve. Then apply moderate force on the brake pedal and start the engine.

Inspection Criteria:

Vacuum Assist (Boost) System:

Brake Reserve Test:

- During Stage 1, the vacuum reserve must be sufficient to assist two full brake applications.

- During Stage 2, downward movement of the brake pedal must be felt when the engine is started.

Leakage Test:

- Line, hose, and clamp must be free of breaks, chafing, collapses, cracks, leaks, looseness, or missing parts.

- Check valve must be correctly installed, operational, free of leaks, and not missing.

- Tank must be free of damage, structural deterioration from corrosion, secure, and not leaking or missing.

- Vacuum pump must operate within manufacturer specifications or achieve and maintain 4.5 kPa (18 in.) of vacuum.

Hydraulic Assist (Boost) System:

Brake Reserve Test:

- Hydraulic assist (boost) must be available, and the system must function as described in manufacturer service instructions.

- Warning or indicator lamps must not indicate a system malfunction.

Leakage Test:

- Engine-driven pump, reservoir, and belt must be free of level two leaks of hydraulic boost fluid.

- Fluid level must be within the indicated range.

- Filler cap must be intact and secure.

- Line and hose must be free of level two leaks of hydraulic boost fluid.

- Must be free of breaks, chafing, collapses, cracks, leaks, looseness, or missing parts.

- Must be securely mounted and of the correct type.

Out of Service / Hazardous Condition:

Vacuum Assist (Boost) System:

- A brake hose or line must not swell under pressure.

- There must be no level 2 leaks in any part of the brake system.

- Applied pedal travel must not exceed 80% of total pedal travel.

- The power assist unit must be operational.

- The check valve must be operational and not missing.

- The brake pedal must move downward when the engine is started with the brakes applied.

Hydraulic Assist (Boost) System:

- A brake hose or line must not swell under pressure.

- There must be no level 2 leaks in any part of the brake system.

- Applied pedal travel must not exceed 80% of total pedal travel.

- The power assist unit must be operational.

- The check valve must be operational and not missing.

- The brake pedal must move downward when the engine is started with the brakes applied.

Summary:

- Brake Reserve Test: Must ensure sufficient vacuum or hydraulic assist for brake applications.

- Leakage Test: Must ensure no leaks, breaks, chafing, collapses, cracks, looseness, or missing parts in the system.

- Inspection Criteria: Must function correctly and not have any leaks or operational issues.

- Out of Service / Hazardous Condition: Must not have any swelling hoses, level 2 leaks, excessive pedal travel, or inoperative power assist units.

23. Steering Lash & Travel

Steering Wheel Test:

- With the front wheels in a straight-ahead position, turn the steering wheel until turning motion can be observed at the front wheels.

- Reference a point on the rim of the steering wheel and align it with a stationary reference point.

- Turn the steering wheel in the opposite direction until motion can be observed at the front wheels.

- Measure the distance between the two reference points.

Acceptable Steering Lash:

Manual Steering:

- Wheel Diameter 500 mm (19.7 in.) or less: 85 mm (3.35 in.)

- Wheel Diameter over 500 mm (19.7 in. ): 100 mm (3.94 in.)

Power Steering:

- Wheel Diameter 500 mm (19.7 in.) or less: 75 mm (2.95 in.)

- Wheel Diameter over 500 mm (19.7 in. ): 87 mm (3.43 in.)

Out of Service / Hazardous Condition:

- Steering lash or free-play is greater than the acceptable distance.

Steering Travel

Steering Travel Test:

- Turn the steering wheel through a full right and left turn.

- If the vehicle has manual steering, raise the vehicle and manually and visually inspect:

- Steering Wheel: Check for any broken, modified, damaged, or loose conditions.

- Operation: Ensure there is no binding or jamming during the cycle.

- Clearance: Ensure there is at least 25 mm (1 in.) clearance between the tire and frame, fender, or other parts.

- Steering Stops: Ensure they are present and properly adjusted.

Out of Service / Hazardous Condition:

- Steering stops are missing.

- Steering binds or jams during rotation.

These requirements ensure that the steering system operates safely and effectively, maintaining proper control of the vehicle

24. Auxiliary Equipment

Auxiliary controls and devices include equipment that is primarily inside a vehicle and includes controls for devices such as:

- PTO (Power Take-Off)

- Wet lines

- Tarp systems

- Vehicle-mounted lifting and transporting devices

- Snow plow

- Dump box

- Front-mount hydraulic pump

- Roll-on roll-off systems

Inspection Requirements:

Condition:

- Check the security of controls and devices visually, manually, and using suitable tools as necessary.

- No functional test is required.

Rejected If:

- The device is in such an unsafe condition that it could be a risk to the driver or a passenger.

- The device is insecure or loose, or in danger of shifting in a way that could impede normal operation of the vehicle.

- There is a level 2 leak of oil or other operating fluid.

Out of Service / Hazardous Condition:

- The control or device is in such an unsafe condition that it is an imminent risk to the driver or a passenger.

- The control or device is insecure or loose, or in imminent danger/risk of shifting in a way that impedes normal operation of the vehicle.

These requirements ensure that auxiliary controls and devices are securely mounted and in safe working condition, preventing any potential hazards during vehicle operation.

25. Floor

Condition:

- Visually and manually inspect the floor and step well covering for any damage or wear.

Rejected If:

- The floor or step well covering is torn, loose, or missing.

- The covering is in a condition that could cause a tripping hazard or impede safe entry and exit from the vehicle.

- The covering is not securely attached to the floor or step well.

- The covering is excessively worn, exposing the underlying material or creating an unsafe surface.

These requirements ensure that the floor and step well coverings are in good condition, securely attached, and safe for use, preventing any potential hazards for the driver and passengers.

26. Door

Condition and Operation:

- Test the operation of each door, including the trunk lid, rear hatch, and partition door between the occupant and cargo area.

- A vehicle equipped with removable doors must be inspected with all doors installed.

Rejected If:

- The door binds or fails to operate as intended.

- The door handle and opener fail to operate or latch on both primary and secondary latches.

- The door is weakened by corrosion in the catch or latch area.

- The hinge is insecurely mounted, weakened by corrosion in the hinge area, or the pins or bushings are cracked, missing, broken, loose, or seized in a manner that the door will not close, latch, or seal properly.

- The door panel is corroded through, separated, welded, repaired, or modified in a way that does not meet OEM or industry standards.

- The seals are missing, out of position, deteriorated, or a gap exists that would be ineffective in preventing exhaust gases from entering the passenger compartment.

Out of Service / Hazardous Condition:

- The door fails to latch on both primary and secondary latches.

- A gap exists and exhaust gases are entering the passenger compartment.

These requirements ensure that all doors on the vehicle are in good working condition, securely attached, and safe for use, preventing any potential hazards for the driver and passengers.

Body Exterior

27. Lamps

- General Condition:

- Visually inspect all lamps for proper operation, mounting, and condition.

Rejected If:

- Any lamp fails to illuminate, is missing, broken, cracked, insecurely mounted, has visible moisture in the interior, or the lens/reflective material has deteriorated.

- Any required lamp/lens or reflector is fitted with a cover.

- The lamp does not meet CMVSS, DOT, or SAE standards.

- An LED lamp has 25% or more of its diodes nonfunctional.

- An LED headlamp has any diode nonfunctional.

- An incandescent headlamp assembly is fitted with an HID bulb.

Specific Lamp Requirements:

- Headlamps:

- Must have two or four headlamps facing the front, clearly visible, white in color, and operated by the headlamp control.

- Must function on both high and low beam.

- Height must be between 559 - 1372 mm (22-54 in.) above the road surface when measured at the center.

- Tail Lamps:

- Must have two tail lamps located at the rear, red in color, and clearly visible.

- Must be operated by the headlamp control.

28. Headlamp Aim

- Aim:

- Ensure that the headlamp aiming device is calibrated according to the manufacturer's instructions.

- Check the aim of the headlamps using the calibrated aiming device.

- Adjusters:

- Inspect the headlamp adjusters to ensure they are functional and allow for proper adjustment of the headlamp aim.

Reject If:

- The headlamp aim is not within the manufacturer's specified range.

- The headlamp adjusters are missing, broken, or inoperative, preventing proper adjustment of the headlamp aim.

Out of Service / Hazardous Condition:

- Not at least one headlamp is operative on low beam.

These requirements ensure that the headlamps are properly aimed to provide adequate illumination of the road ahead without blinding oncoming drivers, enhancing safety for all road users.

29. Reflectors

- Rear Reflex Reflectors:

- Visually inspect the rear reflex reflectors for presence and condition.

- Side Marker Reflectors:

- Visually inspect the side marker reflectors for presence and condition.

- One lens may serve as both a side marker and clearance reflector provided it can be seen from both sides and rear.

Rejected If:

- Any reflector is cracked, broken, missing, obscured, or damaged.

- The reflector does not meet the requirements of CMVSS, SAE, or:

- Rear Reflex Reflectors:

- Fails to have two reflectors located facing rear as far apart as practicable, red in color, and clearly visible.

- Side Marker Reflectors:

- Fails to have four reflectors, with two on each side as close to the corners as practicable, front amber, rear red, and clearly visible.

- For vehicles over 9.1 meters (30 feet) in length, fails to have an intermediate amber reflector on each side.

- Rear Reflex Reflectors:

Out of Service / Hazardous Condition:

- Not at least one operative red tail lamp on the rear of the vehicle.

These requirements ensure that the vehicle's reflectors are in good condition and properly positioned to enhance visibility and safety, especially during low-light conditions.

30. Bumpers & Trailer Hitch

- Condition:

- Visually inspect the bumpers for presence and condition.

- Design:

- Ensure the bumper design meets OEM or industry standards.

Rejected If:

- The bumper or cover is broken, loose, or missing.

- Any section has an exposed sharp edge, is torn, or protrudes in a manner that could be hazardous to the driver, passenger, pedestrian, or cyclist.

- The bumper/reinforcement is missing, loose, broken, cracked, or perforated.

- OEM shock absorbers/crush zones are collapsed, welded to the rail, solid, or not collapsible.

- The distance from the ground to the center of the front and rear bumper reinforcement is not between 380-560 mm (15-22 in.) on passenger cars.

- The distance from the ground to the lowest part of the front bumper reinforcement is higher than 750 mm (29.5 in.) on a truck, multipurpose passenger vehicle, van, or bus with a GVWR of 4,500 kg or less.

- A replacement part does not meet OEM or industry standards.

Out of Service / Hazardous Condition:

- Any component is so insecure or loose that it is an imminent hazard or could become detached from the vehicle.

- Any section has an exposed sharp edge, is torn, or protrudes in a manner that is hazardous to the driver, passenger, pedestrian, or cyclist.

- Any body part or attachment is broken, cracked, perforated, or sagging in a manner that permits the body to contact any moving part.

Trailer Hitch

Inspection Requirements

- Hitch Assembly, Structure, and Attaching Components:

- Inspect the hitch assembly, receiver, drawbar or draw beam, slider, supporting structure, and attachment to the vehicle chassis using suitable tools.

- Secondary Attachments:

- Visually inspect the secondary latch, locking device, safety chain, or cable.

- Pintle Hitch Coupler:

- Test the operation of the pintle hook and latch.

- Ball Type Hitch:

- Test the operation of the coupling and controls according to the manufacturer’s service instructions.

Reject If:

- Hitch Assembly:

- Any part is bent, broken, cracked, or has a broken weld.

- Welded or repaired in a way that does not meet OEM standards.

- Fastener is ineffective, loose, or missing.

- Any part of the hitch assembly is worn beyond manufacturer specifications, abnormally worn, deteriorated, or perforated by corrosion.

- Hinged drawbar bushing is worn beyond manufacturer specifications.

- Air leak or level 2 oil leak from hydraulic components on any slider system.

- Any slider system has a missing or ineffective stop.

- Sliding drawbar pins are missing or worn greater than 3.2 mm (1/8 in. ).

- Hitch assembly is not rated or of an approved design.

- Secondary Attachments:

- Bent, broken, cracked, missing, abnormally worn, or worn beyond manufacturer specifications.

- Any part is ineffective, insecure, loose, or missing.

- Cable clamps are missing, loose, insufficient in quantity, or installed incorrectly.

- Hooks and safety catches are missing, broken, sprung, or ineffective.

- Pintle Hitch Coupler:

- Cracked or fails to close or latch normally.

- Fastener or any structural part is cracked, ineffective, loose, or missing.

- A fastener is less than SAE grade 8 or ISO class 10.9.

- Cast or forged part is cracked or has been repaired by welding.

- Material is worn more than 5 mm (0.197 in.) from the original dimension.

- Ball Type Hitch:

- Bent, cracked, or loose, mounting hole elongated, threads stripped on nut or shank.

- Ball is worn more than 3.0 mm (0.120 in.) from the original dimension.

- Welded or repaired in a way that does not meet OEM standards.

- Part is bent, broken, or cracked.

- Weld is broken or cracked.

- Bent, cracked, or loose.

- Abnormally deteriorated or perforated by corrosion.

- Inoperative or fails to adjust properly.

Out of Service / Hazardous Condition:

- Any crack, break, or damage in the stress or loading area of the coupling device or structure.

- Any component is damaged or worn to the degree that it is no longer effective.

- Welded or repaired in a way that does not meet OEM standards and an imminent failure appears likely.

- Air leak or level 2 oil leak from hydraulic components on any slider system.

- Any slider system has a missing or ineffective stop.

- Wear on hitch or lunette (eye) exceeds 10 mm (0.393 in. ).

- Any component is broken, cracked, or missing.

- Bent, damaged, improperly repaired, loose, or worn to the degree that it is no longer effective.

- Improper type or inadequate capacity.

These requirements ensure that the bumpers and trailer hitch are in good condition and properly secured to enhance safety for all road users.

31. Body, Hood, and Trunk

- Condition:

- Visually inspect the body for any damage, corrosion, or modifications.

- Body Mount/Support:

- Ensure the body is securely mounted and supported.

- Body Molding or Trim:

- Check for loose, protruding, or damaged molding or trim.

- Fender (includes inner wheel panel):

- Inspect for presence, condition, and proper fit.

Rejected If:

- Any section is in a condition that could be hazardous to the driver, passenger, pedestrian, or cyclist due to being loose, protruding, torn, or having an exposed sharp edge.

- Corroded, perforated, or torn in a manner that reduces structural integrity of a panel or floor, or allows exhaust gases to enter the occupant compartment.

- Modified in a manner that may reduce structural integrity (unless the condition or the repair is approved by the OEM, or an engineer).

- Body component integrity is reduced due to a loose body component, broken weld, missing fastener, or failed adhesive.

- Body panel or floor is welded or repaired in a way that does not meet OEM or industry standards.

- Body panels are separated, misaligned, structural shapes are distorted, or there are indications of metal heating.

- Body mount/support allows an abnormal amount of movement, is broken, cracked, loose, or has missing parts.

- Improper mount used that does not meet OEM or industry standards.

- Support is cracked, broken, or bulging.

- Welded or repaired in a way that does not meet OEM or industry standards.

- Body molding or trim is in a condition that could be hazardous to the driver, passenger, pedestrian, or cyclist due to being loose, protruding, torn, or having an exposed sharp edge.

- Fender is missing, not full width of tires, section torn away, or corroded so that road spray is not controlled.

- Corroded or damaged in a manner that OEM installed lamps cannot be properly secured.

- Repaired in a way that does not meet OEM or industry standards.

- Fitted in a manner to cause interference with the steering mechanism or cause rubbing of tires when suspension is bottomed and steering is moved from stop to stop (includes rear wheels).

Out of Service / Hazardous Condition:

- Any component is so insecure or loose that it is an imminent hazard or it could become detached from the vehicle.

- Any section has an exposed sharp edge, is torn, or protrudes out in a manner that is hazardous to the driver, passenger, pedestrian, or cyclist.

- Any body part or attachment is broken, cracked, perforated, or sagging in a manner that permits the body to contact any moving part.

Hood

- Condition:

- Test the operation of the hood or engine enclosure doors, attachment, latches, and safety devices.

- Latches (Primary or Secondary):

- Ensure latches are functional and secure.

- Hinges:

- Inspect for presence, condition, and proper operation.

- Support/Assist Springs, Dampeners, Cables, Pins:

- Check for proper function and condition.

Rejected If:

- Hood/engine cover is missing, damaged, insecure, or deteriorated in a manner that it is likely to become detached.

- Any repair or modifications by methods other than those approved by the OEM or industry standards.

- Any replacement part does not meet OEM or industry standards.

- Latches are broken, missing, seized, insecurely mounted, or inoperative.

- Effectiveness is compromised due to deteriorated condition (e.g., rubber or similar type of latch) or of inferior substitute.

- Fails to open or close normally.

- Welded or repaired in a way that does not meet OEM standards.

- Hinges are missing, broken, cracked, seized, welded, inoperable, or have parts missing.

- Insecure, abnormally worn, deteriorated due to corrosion.

- Support/assist springs, dampeners, cables, pins are broken, insecurely attached, missing, or of inferior substitute.

Out of Service / Hazardous Condition:

- Both primary and secondary latches are inoperative.

Trunk

- Condition and Operation:

- Test the operation of the trunk lid, rear hatch, and partition door between the occupant and cargo area.

Rejected If:

- Trunk lid, rear hatch, or partition door binds, fails to operate as intended.

- Door handle and opener fail to operate or latch on both primary and secondary latches, weakened by corrosion in catch or latch area.

- Hinge is insecurely mounted, weakened by corrosion in hinge area, pins or bushings are cracked, missing, broken, loose, or seized in a manner that the door will not close, latch, or seal properly.

- Door panel is corroded through, separated, welded, repaired, or modified in a way that does not meet OEM or industry standards.

- Seals are missing, out of position, deteriorated, a gap exists, or any condition that would be ineffective in preventing exhaust gases from entering the passenger compartment.

Out of Service / Hazardous Condition:

- Door fails to latch on both primary and secondary latches.

- Gap exists and exhaust gases are entering the passenger compartment.

These requirements ensure that the body, hood, and trunk are in good condition and properly secured to enhance safety for all road users.

32. Fenders & Mud Flaps

- Condition:

- Fenders and mudflaps must be secure, not loose or missing.

- They should not have sections torn or worn away that would prevent them from controlling road spray.

- They must be fitted in a manner that does not interfere with the steering mechanism or cause rubbing of tires when the suspension is bottomed and the steering is moved from stop to stop (including rear wheels).

- Width:

- Fenders and mudflaps must cover the full width of the tires (tread face).

- Height:

- The height from a level ground surface to the bottom of the mudflap or body overhang should not exceed 10 inches (254 mm) or one-third of the distance from the mudflap or body overhang to the center of the wheel.

Out of Service / Hazardous Condition:

- Any component that is so insecure or loose that it is an imminent hazard or could become detached from the vehicle.

- Any section that has an exposed sharp edge, is torn, or protrudes in a manner that is hazardous to the driver, passenger, pedestrian, or cyclist.

- Any body part or attachment that is broken, cracked, perforated, or sagging in a manner that permits the body to contact any moving part.

33. Frame, Mounts, and Unibody

Frame Mounts

- Condition:

- Visually inspect the frame mounts for any damage, corrosion, or modifications.

- Frame Fasteners:

- Ensure all fasteners are present, secure, and in good condition.

- Cross-Members:

- Inspect cross-members for integrity and proper attachment.

- Sub-Frame Assembly:

- Check the sub-frame assembly for any signs of damage or improper repairs.

Rejected If:

- Frame is welded, modified, or repaired in a way that does not meet OEM or industry standards.

- Frame is cracked, broken, bent, or kinked.

- Frame is perforated or separated due to corrosion between mount and frame member.

- Frame is rusted or corroded to a depth sufficient to become weakened.

- Frame has a bulge caused by corrosion resulting in distortion of 10 mm (0.39 in.) or more (unless the condition or the repair is approved by the vehicle OEM, or an engineer).

- Any condition of the frame assembly allows a frame component, or a part of the body to contact a moving part, or power train to move out of its normal position, or affects the ability to maintain the wheel alignment within the manufacturer's specified range.

- Frame fasteners are corroded so as to be ineffective, missing, loose, or of inferior substitute.

- Cross-members are missing, bent, loose, cracked, broken, or missing.

- Cross-members are cut, notched, rusted, or corroded to a depth sufficient to cause weakness.

- Cross-members are repaired using material or method that does not meet OEM or industry standards.

- Any condition of a cross-member allows a frame component, or a part of the body to contact a moving part, or power train to move out of its normal position, or affects the ability to maintain the wheel alignment within the manufacturer's specified range.

- Sub-frame assembly is bent, broken, cracked, loose, or missing.

- Sub-frame assembly is cut, notched, rusted, or corroded to a depth sufficient to cause weakness.

- Sub-frame assembly is repaired using material or method that does not meet OEM or industry standards.

- Any condition of the sub-frame assembly allows a frame component or a part of the body to contact a moving part, or power train to move out of its normal position, or affects the ability to maintain the wheel alignment within the manufacturer's specified range.

Out of Service / Hazardous Condition:

- Any frame member is broken, sagged, or cracked.

- Any frame member or component fails to adequately support directional stability or support components.

- Energy management structure is compromised or rendered ineffective.

- Imminent failure appears likely due to a frame member that is damaged or deteriorated, or has been repaired using material or method that does not meet OEM or industry standards.

Unibody Construction

- Load Carrying Panels, Structural Elements, and Mounts:

- Inspect all load-carrying panels, structural elements, and mounts for integrity and proper attachment.

- Strut Towers and Suspension Mount Support Structure:

- Check strut towers and suspension mount support structures for any signs of damage or improper repairs.

- Radiator Supports, A, B, C Pillars, Rocker Panels, Cab Corners:

- Inspect these components for any signs of damage, corrosion, or improper repairs.

Rejected If:

- Mounts are bent, broken, cracked, loose, or missing.

- Panels are damaged, modified, or corroded to an extent sufficient to cause structural weakness or energy management structures are compromised or rendered ineffective.

- Panels are welded or repaired in a way that does not meet OEM or industry standards or completed repair is missing corrosion-resistant coating.

- Any condition of the unitized body allows a part of the body to contact a moving part or power train to move out of its normal position, or affects the ability to maintain the wheel alignment within the manufacturer's specified range.

Out of Service / Hazardous Condition:

- Any component is so insecure or loose that it could become detached from the vehicle.

- Any condition of a unitized body component allows a part of the body or power train to move or shift out of its normal position, or to contact a moving part.

- Imminent failure appears likely due to a body component that is damaged or deteriorated, or has been repaired using material or method that does not meet OEM or industry standards.

These requirements ensure that the frame mounts and unibody construction are in good condition and properly secured to enhance safety for all road users.

UNDERCARRIAGE

34. Wheels & Tires

Tires

- Tread Depth:

- Use a tire tread depth gauge to measure the tread depth throughout a continuous circumferential band on the tread of all major grooves of the tread width. Do not measure on wear bars.

- Tread Condition:

- Visually inspect the tread for any cracks, cuts, flat spots, or missing pieces.

- Retread (Re-cap, Remold, or Rebuilt Tire):

- Ensure retreaded tires are not installed on an active steering axle.

- Regrooving:

- Check if regrooving has been performed on a tire not marked "Regroovable".

- Sidewalls:

- Visually inspect the sidewalls for any damage, bulges, or improper repairs.

- Tire Inflation:

- Use a gauge to check tire pressure and inspect valve stems and tire inflation systems.

- Manufacturer Markings and Matching of Tires:

- Ensure tires are properly marked and matched according to manufacturer specifications.

Rejected If:

- Tread depth is less than 1.6 mm (0.063 in.) in any one spot, or has wear bars exposed.

- Crack or cut is greater than 25 mm (1 in.) in length and extends deeper than a major tread groove.

- Crack or cut extends into the body cord, or any body cord is exposed.

- Any flat spots are evident across the tread face.

- Tread is less than 1.6 mm (0.063 in.) in a cupped area or cupped to wear bars.

- Any piece of original tire tread is missing, and the longest dimension across the missing section is greater than 25 mm (1 in. ).

- Retreaded tire is installed on an active steering axle.

- Retread material is loose, missing, or separated at the interface where the retread is bonded to the tire casing.

- Regrooving has been performed on a tire not marked "Regroovable".

- Ply separation is evident, or body cords are exposed.

- Tire has a bump or bulge caused by tread or sidewall separation.

- Casing is broken or distorted.

- Distortion is caused by incorrect rim width.

- Presence of plug-type repair, or rubber-coated or cured rubber plug is used in the sidewall.

- UV degradation damage is more than 3 mm (1/8 in.) deep.

- Wheel/rim size does not match tire size.

- Required tire is missing.

- Mismatching of tire type.

- A directional tire is incorrectly located.

- Tire is labeled "Not for Highway Use" or in any way that indicates the tire is not intended for on-road use.

- Tire is not labeled indicating DOT or CMVTSS compliant.

- Tire pressure is more than 10% above or below the range as marked on the sidewall.

- Tire is leaking or inflation cannot be maintained within the recommended range.

- Valve stem is cracked, damaged, or leaking.

- Valve stem is inaccessible, preventing gauging of pressure or re-inflation.

- Valve stem cap is damaged or missing.

- Tire inflation system is in a condition that any part of it could be hazardous to a person or is in danger of falling off.

Out of Service / Hazardous Condition:

- Less than 1.6 mm (0.063 in.) of tread in any spot on front tires.

- Any part of the belt, breaker strip, or casing ply is visible in the tread area.

- Visible bump or bulge in the tread area indicating separation.

- Regrooved, recapped, or retreaded tire on the front steering axle.

- Retread material is loose, missing, or separated.

- Sidewall is cut or damaged, exposing the cord.

- Visible bump or bulge in the sidewall area greater than 9 mm (3/8 in.) in height.

- Rubber-coated or cured rubber plugs are used in the sidewall.

- Bias and radial tires on the same axle.

- Any tire labeled "Not for Highway Use" or in any way that indicates the tire is not intended for on-road use.

- Any tire is inflated to 50% or less of the maximum inflation pressure marked on the sidewall.

- Tire is leaking.

- Tire inflation system is in a condition that any part of it is hazardous to a person or is in danger of falling off.

Wheels

- Condition:

- Inspect wheels for any damage, cracks, or improper repairs.

- Matching:

- Ensure wheels are properly matched according to manufacturer specifications.

- Disc Wheel System:

- Inspect the installation and condition of the disc wheel system.

- Wheel Fasteners (Nuts, Bolts, and Studs):

- Check the installation and condition of wheel fasteners.

- Wheel Hub:

- Inspect the wheel hub for any damage, proper lubrication, and secure attachment.

Rejected If:

- Wheel/rim is bent, broken, cracked, damaged, or distorted.

- Wheel/rim has been welded or repaired in a way that does not meet OEM standards.

- Wheel/rim is damaged or discolored as a result of heating.

- Any wheel spacer is installed between the wheel and wheel mounting surface that does not meet OEM standards.

- Wheel/rim size does not match tire size.

- Vehicle has mismatched rims on the same axle.

- Incompatible wheel or component is used on a wheel system, or the wheel is incorrectly installed.

- There is evidence of a loose or ineffective fastener.

- There is evidence of damage or deterioration, foreign material, excessive or uncured paint on a hub, drum, or wheel mounting face.

- Bolt/stud hole is elongated.

- Incorrect fastener type, thread direction, or style is installed.

- Any nut is not fully engaged with the stud or bolt.

- Any fastener is bent, broken, damaged, or missing.

- Wheel hub is repaired by welding.

- Wheel hub is bent, broken, cracked, damaged, or distorted.

- Bearing cup is loose in the hub bore.

- Any bolt/stud hole is enlarged or damaged in a way that prevents proper fitting and retention of studs.

- Level 2 leak of bearing lubricant from an oil-lubricated hub.

- Seal is allowing grease to be lost from the hub.

- Seal is out of position.

- Lubricant level is below the indicated minimum, or lubricant is contaminated with moisture or metal fragments.

- Level 2 leak of bearing lubricant from the hub or hub cap.

- Grease is leaking from the hub.

- Hub cap is cracked, loose, or missing.

Out of Service / Hazardous Condition:

- Wheel/rim, or any weld, is broken or cracked.

- Any welded repair on an aluminum wheel.

- Wheel/rim has been welded or repaired in a way that does not meet OEM standards.

- Bolt/stud hole is elongated.

- Wheel is loose.

- Any wheel nut or stud is broken, cracked, loose, missing, or threads are stripped.

- Any condition that exposes the internal components of the wheel hub.

- Any evidence of overheating of the hub or lubricant, or lack of lubricant.

35. Wheel Bearings

- Axle Raised:

- Raise the axle sufficiently to rotate the wheel and hub assembly.

- Rotation Check:

- Rotate the wheel by hand through several full revolutions to check for bearing roughness or binding.

- End-Play/Adjustment Check:

- Check wheel bearing end-play/adjustment by pushing the wheel assembly or hub inward and outward parallel to the axle centerline.

- Confirm bearing axial end-play/adjustment on a non-sealed type hub with a dial gauge if necessary.

- Pre-Set, Unitized, or Extended Service Bearings:

- For pre-set, unitized, or extended service bearings, refer to the service literature provided by the manufacturer to confirm proper diagnosis before rejecting the vehicle.

Rejected If:

- Axial end-play does not meet OEM standard or industry standard, or when specification is not provided, is less than 0.02 mm (0.001 in.) or more than 0.13 mm (0.005 in. ).

- Binding or roughness is detected while rotating the bearing.

- Bearing adjustment locking device is missing, not engaged, or non-functional.

- Race or roller is damaged or shows evidence of overheating.

- Bearing fit onto the spindle or axle stub does not meet OEM or industry standard.

- Spindle or axle stub is cracked or damaged in a way that does not meet OEM or industry standard.

- Bearing condition or fit of the bearing onto the spindle prevents proper end-play or adjustment from being maintained.

Out of Service / Hazardous Condition:

- Axial end-play is so excessive that imminent failure seems likely.

- Any evidence of overheating of bearings, hub, or lubricant, or lack of lubricant.

- Binding or roughness is detected while rotating the bearing.

These requirements ensure that the wheel bearings are in good condition and properly adjusted to enhance safety for all road users.

36. Ball Joints King Pins

- Check Ball Joints as per OEM Instructions:

- Follow the original equipment manufacturer (OEM) instructions for checking ball joints.

- Use a dial indicator to measure horizontal and vertical movement as defined in the OEM service manual.

- Visual and Manual Inspection:

- Inspect the condition of the ball joints visually and manually.

- Ball Joints with Wear Indicators:

- Inspect ball joints with wear indicators while the ball joints are loaded.

Rejected If:

- Condition:

- Ball joints are injected, and wear exceeds the manufacturer's specifications.

- Seals are missing or cracked open.

- Retainers are improper or loose.

- Wear indicators indicate that the ball joints are worn beyond manufacturer specifications or are flush with the cover surface.

- Ball Joints with Wear Indicators:

- The surface of the wear indicator is flush with or inside the cover surface.

- Wear exceeds the manufacturer's specifications.

Out of Service / Hazardous Condition:

- The ball joint does not lock into position.

King Pins Inspection

- Raise Vehicle:

- Raise the vehicle to unload the kingpins and apply the brakes to eliminate wheel bearing movement.

- Check Movement:

- With a dial indicator or a fixed device placed at the wheel, use a bar for leverage to attempt to rock the wheel in and out.

- Observe horizontal movement at the extreme top or bottom of the tire.

- Place a bar under the tire and check for vertical movement between the spindle support and axle.

- Visual and Manual Inspection:

- Inspect the condition of the kingpins visually and manually.

Rejected If:

- Horizontal Movement:

- Not within manufacturer's specification or, if not given, in excess of:

- 5 mm (3/16 in.) for wheels 508 mm (20 in.) or more.

- 3 mm (1/8 in.) for wheels less than 508 mm (20 in. ).

- Not within manufacturer's specification or, if not given, in excess of:

- Vertical Movement:

- Not within manufacturer's specifications or, if not given, in excess of 2.5 mm (0.098 in. ).

- Condition:

- Binding, seized, or thrust bearing seized or binding.

Out of Service / Hazardous Condition:

- Binding or seized kingpin or thrust bearings.

These requirements ensure that both ball joints and king pins are in good condition and properly maintained to enhance vehicle safety and performance.

37. Rack and Pinion Steering

- Visual and Manual Inspection:

- Inspect the rack and pinion steering system visually and manually for any signs of wear, damage, or improper installation.

- Check for Free Play and Lash:

- With the engine off and the wheels on the ground, rock the steering wheel left and right and observe movement in the steering components.

- Measure the total movement (lash) at the steering wheel rim until turning motion can be observed at the front wheels.

- Inspect Components:

- Inspect the tie rods, tie rod ends, and other related components for wear, damage, or looseness.

- Check the steering gear housing and mounting for cracks, looseness, or damage.

- Inspect the bellows (clamp and boot) for splits, tears, or missing parts.

- Check the inner socket assembly for wear beyond OEM standards.

Rejected If:

- Steering Lash:

- Total movement is greater than OEM standard or, if OEM standard is not available, exceeds:

- 12 mm (0.472 in.) for power rack and pinion assembly.

- Total movement is greater than OEM standard or, if OEM standard is not available, exceeds:

- Tie Rod and Drag Link:

- Cracked, broken, kinked, bent, welded, or reinforced.

- Worn so movement is evident, bent, field welded, injected, attaching nut loose, threads stripped, or repaired in nut or on shank.

- Not an automotive type or does not meet OEM standard.

- Steering Gear:

- Housing or bracket cracked, insecurely mounted, bolts loose or missing.

- Bellows (clamp and boot) split, torn, or missing.

- Inner socket assembly worn beyond OEM standard.

- Mounting Brackets:

- Cracked, damaged, bolts or clamps missing or loose.

- Insulators missing or loose.

- Cotter Pins:

- Missing or of inferior substitute.

- Steering Column:

- Loose, mounted insecurely, mounting bolts missing or loose, tilt or adjustable column does not comply with OEM free play and mounting standards.

- Coupler to box misaligned or deteriorated, oil contaminated.

- Clamp, bolt, nut, or locking roll pin is loose or missing.

Out of Service / Hazardous Condition:

- Steering Lash or Free-Play:

- Steering lash or free-play is greater than the distance shown below:

- 75 mm (2.95 in.) for power steering with a wheel diameter of 500 mm (19.7 in.) or less.

- 87 mm (3.43 in.) for power steering with a wheel diameter over 500 mm (19.7 in. ).

- Steering lash or free-play is greater than the distance shown below:

- Steering Components:

- Any steering component is home-built or repaired by welding.

- Nuts loose on tie rod ends, pitman arm, drag link, or steering idler arm.

- Steering column bolts are loose or missing, or any positioning parts allow movement from its normal position.

- Any universal joints are field welded.

- Steering wheel not secure.

- Adjuster sleeve loose.

- Steering box or rack and pinion unit mounting bolts are loose or missing.

- Frame or mounting bracket is loose or cracked.

- Pitman arm is loose on the steering gear output shaft spline or field welded.

- Ball and sockets show looseness in alignment with the shank or neck of the ball in excess of 3 mm (0.118 in.) or adjusting sleeve loose.

- Any socket injected.

These requirements ensure that the rack and pinion steering system is in good condition and properly maintained to enhance vehicle safety and performance.

38. Engine Transmission Mounts

- Visual and Manual Inspection:

- Inspect the engine and transmission mounts visually and manually for any signs of wear, damage, or improper installation.

- Check for Condition and Security:

- Ensure that the mounts are securely attached and in good condition.

Rejected If:

- Condition:

- Mounts are missing, loose, bent, or have missing bolts.

- Insulators are missing, broken, deteriorated, oil-contaminated, or inappropriate substitutes.

- Mounts are cracked or have broken welds.

- Any part of the mount is insecure or deteriorated in a manner that it is likely to become detached.

- Attachments:

- Bolts are missing, broken, or loose.

- Mounts are repaired or modified in a way that does not meet OEM standards.

Out of Service / Hazardous Condition:

- Mounts:

- Any engine or transmission mount is missing, broken, or so deteriorated that it fails to support the engine or transmission securely.

- Any condition of the mounts allows the engine or transmission to move out of its normal position, affecting the vehicle's stability and safety.

These requirements ensure that the engine and transmission mounts are in good condition and properly maintained to enhance vehicle safety and performance.

39. Steering Linkage